Various machining

We process raw materials as designated and deliver them to our users. Users can simplify their order placement with us. We cope with various types of machining ranging from small parts processing to processing of mass foundation such as common plates. We can process all kinds of materials including iron, nonferrous metals or plastics. We deliver finished goods when they are processed as designated in drawings.

・Precision melt cutting NC profile melt cutting

・Large and small milling machine

・Grinding, Rotary grinding

・NC engine lathe, Normal engine lathe

・Horizonal milling machine

・Spark erosion, Wire erosion

・Laser cut Plasma cut

・Profile machining

*Fine plasma melt cutting machine

We deliver high accuracy dimensions and high quality cutting section products by Fine plasma melt cutting machine.

Various Heat treatment and Surface treatment

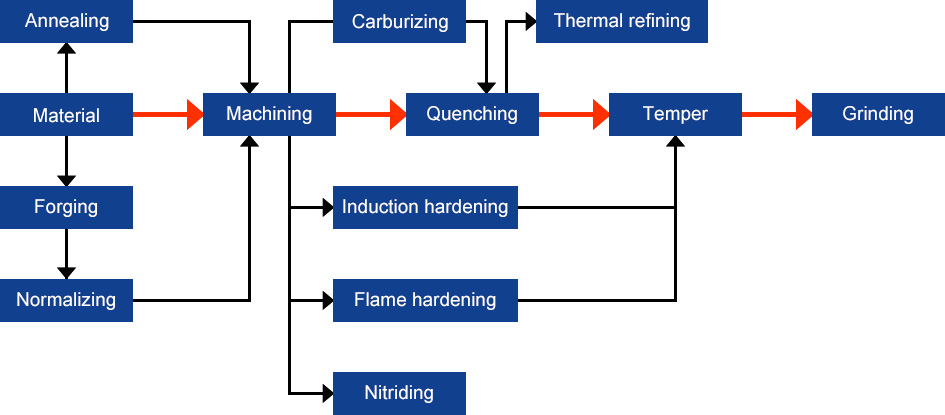

Heat treatment process

・Induction hardening, Vacuum quenching, Annealing, Shot blasting, Thermal refining, Carburizing quenching, Nitriding quenching

・Galvanized, Hard chrome plating

・Tufftride treatment, Fe3O4 treatment

One point lesson

<What is heat treatment?>

・Heat treatment has two type of method. One of General heat treatment the other is Surface heat treatment.

・General heat treatment process is Quenching, Annealing, Normalizing and Temper.

・Surface heat treatment is Carburizing, Thermal refining, Nitriding and Induction hardening.

・When steel cold fast it will become hard, when steel cold slowly it will become soft.

<General heat treatment>

・Quenching…Steel heat over 730° and rapid cooling, Steel is hardened.

・Annealing…Steel heat over 730° and slow cooling, Steel is softly.

・Normalizing…Steel heat over 730° and naturally cooling, Steel is returned to original nature.

・Temper…Steel heat under 730° and rapid cooling, Steel is more hardened when it treated in lower temperature.

*Usually it is finished Quenching + Temper

<Surface heat treatment>

Surface treatment has Induction hardening, Nitriding and others.

・Carburizing…Steel surface is more hardened.

・Thermal refining…It is not only hardened but also toughness for against break.

・Nitriding…It does not need quenching and temper.

・Induction hardening